2KW 220V 50Hz Roller Coating Equipment With Paint Coating Material Power Supply

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Osmanuv |

| Certification: | ISO9001 And CE |

| Model Number: | 1320 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden Box |

| Delivery Time: | 35-45 Working days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | According to customer's demand |

|

Detail Information |

|||

| Power Consumption: | 2KW | Roller Speed: | 0-20m/min |

|---|---|---|---|

| Dimension: | 1800*1000*1200mm | Max Coating Thickness: | 0.2-3mm |

| Weight: | 500kg | Roller Diameter: | 200-400mm |

| Noise Level: | ≤75dB | Air Pressure: | 0.4-0.6Mpa |

| Highlight: | 220V Roller Coating Equipment,2KW Roller Coating Equipment |

||

Product Description

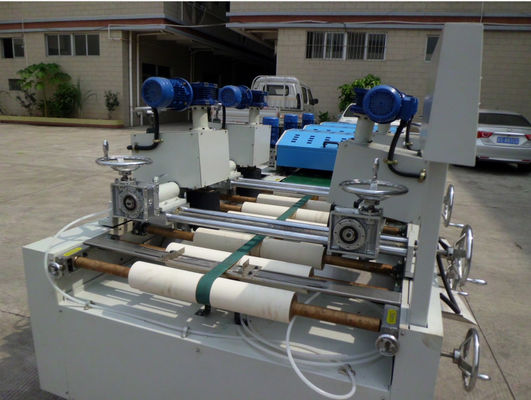

220V/50Hz Roller Coating Equipment With Paint Coating Material Power Supply

Product Description:

Roller Coating Equipment is a high-efficiency coating machine that is perfect for conveyor roller manufacturing and anilox roller cleaning. It is equipped with a 500kg frame and uses a power supply of 220V/50Hz. Its power consumption is only 2KW and its air pressure is adjustable from 0.4Mpa to 0.6Mpa. The coating efficiency can reach up to 90%. With its high speed coating ability, Roller Coating Equipment is the perfect choice for any manufacturing or cleaning needs.

Features:

- High Speed Coating Machine,Power Supply: 220V/50Hz, Roller Speed: 0-20m/min

- Heavy Duty Conveyor Rollers,Max Coating Thickness: 0.2-3mm,Roller Diameter: 200-400mm

- Seamless Coating,Air Pressure: 0.4-0.6Mpa

Technical Parameters:

| Product Name | Roller Coating Equipment |

|---|---|

| Power Consumption | 2KW |

| Noise Level | ≤75dB |

| Coating Method | Roller Coating |

| Roller Speed | 0-20m/min |

| Coating Uniformity | ≤±2% |

| Dimension | 1800*1000*1200mm |

| Air Pressure | 0.4-0.6Mpa |

| Max Coating Thickness | 0.2-3mm |

| Power Supply | 220V/50Hz |

| High Speed Coating Machine | Yes |

| Anilox Roller Cleaning Equipment | Yes |

| Conveyor Roller Manufacturing Machine | Yes |

Applications:

Roller Coating Equipment is a heavy duty conveyor roller which is widely used in the automatic spray paint production line, coil coating line and other industrial application. It features advanced technology and high efficiency, with a coating efficiency of ≥90%, power supply of 220V/50Hz, maximum coating thickness of 0.2-3mm and roller speed of 0-20m/min. It is easy to operate and maintain, and is certified with ISO9001. The model number is 1320, and the minimum order quantity is 1 set. The price is negotiable and the packaging details are wooden box. The delivery time is 40 work days and the payment terms are T/T, Western Union. The supply ability is according to customer's demand.

Anilox roller cleaning equipment is the perfect companion for the roller coating equipment, helping to keep the rollers clean and free from debris or other contaminants. It helps to ensure the highest quality of coating, with even and consistent results. It is designed to be safe and efficient, making it easy to use and maintain.

The Automatic Spray Paint Production Line is the ideal choice for many industrial applications, providing a safe and efficient way to produce high quality spray paint. It is designed to be easy to operate and maintain, and is certified with ISO9001. It features a high efficiency coating efficiency of ≥90%, power supply of 220V/50Hz, maximum coating thickness of 0.2-3mm and roller speed of 0-20m/min. The model number is 1320, and the minimum order quantity is 1 set. The price is negotiable and the packaging details are wooden box. The delivery time is 40 work days and the payment terms are T/T, Western Union. The supply ability is according to customer's demand.

The Coil Coating Line is a perfect choice for many industrial applications, providing a safe and efficient way to produce high quality coating. It is designed to be easy to operate and maintain, and is certified with ISO9001. It features a high efficiency coating efficiency of ≥90%, power supply of 220V/50Hz, maximum coating thickness of 0.2-3mm and roller speed of 0-20m/min. The model number is 1320, and the minimum order quantity is 1 set. The price is negotiable and the packaging details are wooden box. The delivery time is 40 work days and the payment terms are T/T, Western Union. The supply ability is according to customer's demand.

Roller Coating Equipment from Automatic Spray Paint Production Line, Coil Coating Line, and other industrial applications is a heavy duty conveyor roller which is designed to provide excellent performance, with a coating efficiency of ≥90%, power supply of 220V/50Hz, maximum coating thickness of 0.2-3mm and roller speed of 0-20m/min. It is easy to operate and maintain, and is certified with ISO9001. The model number is 1320, and the minimum order quantity is 1 set. The price is negotiable and the packaging details are wooden box. The delivery time is 40 work days and the payment terms are T/T, Western Union. The supply ability is according to customer's demand.

Customization:

Our Automatic Spray Paint Production Line is the perfect roller coating equipment for your needs. Our machine is certified with ISO9001, and can be customized according to your needs. With a Minimum Order Quantity of 1 Set, the Price is Negotiable and the Packaging Details are Wooden box. We guarantee a Delivery Time of 40 work days, with payment methods of T/T or Western Union. We also guarantee Supply Ability according to your customer's demand. Our machine's Roller Speed is 0-20m/min, with a Coating Efficiency of ≥90%, a Weight of 500kg, a Roller Diameter of 200-400mm, and a Max Coating Width of 1000mm. Our machine also has Heavy Duty Conveyor Rollers, Anilox Roller Cleaning Equipment, and other features to make your production line run smoothly and efficiently.

Support and Services:

Roller Coating Equipment offers technical support and services to its customers in the following ways:

- Providing installation and operational instructions

- Responding to customer inquiries in a timely manner

- Providing technical advice and support

- Carrying out preventive maintenance and repairs

- Providing spare parts and consumables

- Offering product upgrade services

Packing and Shipping:

The packaging and shipping of Roller Coating Equipment usually comprises of the following steps:

- The equipment is securely packed in protective packaging material and bubble wrap.

- The equipment is loaded onto the delivery vehicle.

- The delivery vehicle is secured with straps or other fastening mechanisms.

- The delivery vehicle is driven to the appropriate destination.

- The equipment is unloaded from the delivery vehicle.

- The equipment is inspected for damages or other issues.

- The customer is notified that the equipment has been delivered.

FAQ:

- Q: What is the brand name of the Roller Coating Equipment?

- A: The brand name of the Roller Coating Equipment is Automatic Spray Paint Production Line.

- Q: What is the model number of the Roller Coating Equipment?

- A: The model number of the Roller Coating Equipment is 1320.

- Q: Where is Roller Coating Equipment manufactured?

- A: The Roller Coating Equipment is manufactured in China.

- Q: Does the Roller Coating Equipment have ISO9001 certification?

- A: Yes, the Roller Coating Equipment has ISO9001 certification.

- Q: What is the minimum order quantity for the Roller Coating Equipment?

- A: The minimum order quantity for the Roller Coating Equipment is 1 Set.